About Us

ブランド紹介 – 日本の伝統工芸の保護と再生

FORTUNA Tokyo(フォーチュナトウキョウ)は日本の伝統工芸を守り、現代にリバイバルすることをミッションとした国産ブランド。伝統とトレンドを融合させた”和モダン・クラシック”なアイテムを提案しており、西陣織シルクネクタイや京扇子、メンズウェアに加えて革小物まで幅広く商品を展開。

ドラマやTVでタレント着用多数の実績があり、2015年には経済産業省の「Cool Japan」支援のもと、香港ファッションウィークでファッションショーを行い、2016SSコレクションを披露。西陣織シルクネクタイの他に国産のメンズポロシャツを発表。

2017年10月にAmazon Fashion Week Tokyo(東京コレクション)に参加し、2018SSコレクション「SAMURAI REPRISE」を披露。ランウェイではGallery SHINSEIDOとタイアップし、日本画家として高名な千住博氏の「ウォーターフォール」が展示され、和のファッションとアートの融合のファッションショーを開催し、多くの観客を動員、国内や海外のメディアに多数取り上げられました。

2018年8月からISETANシンガポールで西陣織シルクネクタイや国産ポロシャツの取り扱い開始。

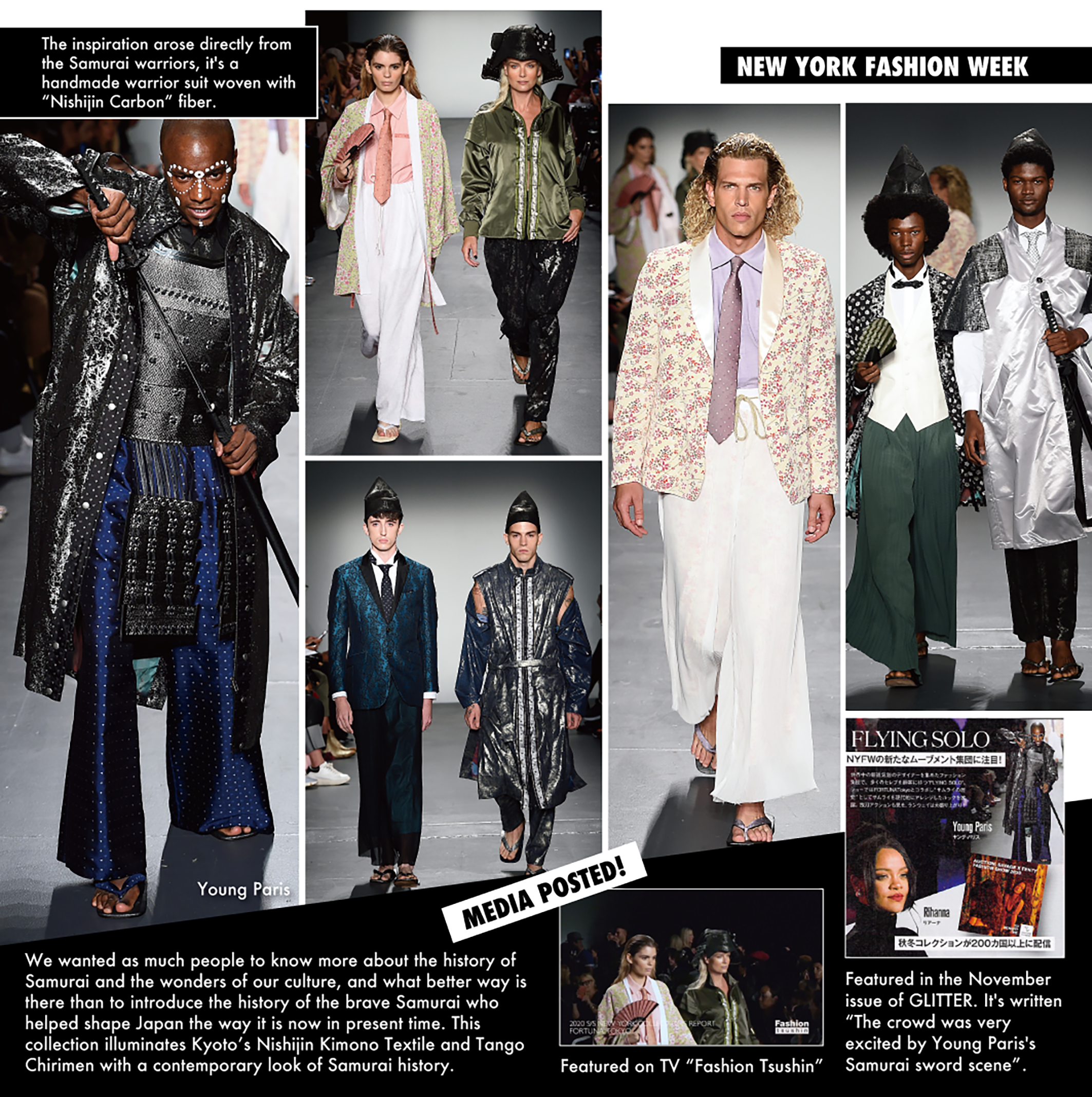

2019年7月にはニューヨークのマンハッタンで販売を開始しました。2019年9月にニューヨークファッションウィークでランウェイショーを行い2020SSコレクションを発表。その様子がファッション通信でテレビ放送され、西陣織で作られたサムライの衣装は反響を呼び、国内外の数多くのメディアに取り上げられ、ハリウッドセレブも多数着用しています。

ブランド概要

ブランド名: FORTUNA Tokyo(フォーチュナトウキョウ)

ブランド創設年月日: 2011年7月11日

デザイナー紹介

デザイナー: Akiko Koba

グラフィックデザイナー出身、母から受け継いだ西陣織の着物に魅せられ、日本の伝統の織物をメインコンセプトにした「FORTUNA Tokyo」を立ち上げました。イギリス在住経験を活かし英国調のトラディッショナルと和を掛け合わせたデザインが得意で、”和×グラフィックデザイン×日本の職人技”をブランドコンセプトとし、西陣織シルクネクタイや西陣織を使用したシルクの京扇子を商品化。

ショーコレクションでは西陣織ネクタイのシルクを使用した着物コートや浴衣の生地を使った和柄のパンツ等を発表。

西陣織や日本の伝統工芸、国産にこだわったものづくりを行い、経済産業省のCool Japanプロジェクトに選出され、2015年度は香港を中心に海外展開。

2017年10月にはAmazon Fashion Week Tokyo(東京コレクション)に参加し、ランウェイショーを披露、東京から世界へ日本のものづくりや文化を発信。

2019年の9月にはFlying Soloとタイアップし、ニューヨーク・ファッション・ウィークで「2020SS SAMURAI HISTORY」を披露。初出場ながら、ショーのオープニングに抜擢されるなど、国内・外のメディアからの関心も高く、ショーの様子やデザイナー・インタビューがTV放映されました。VOGUE UKの「デザイナープロフィール」やGQ、VANITY FAIRをはじめとするメディアに多数掲載されており、ハリウッドセレブ御用達アイテムも続々と誕生。

今後も日本の伝統や素晴らしさをモダンな商品としてアレンジし、積極的に海外に向けて日本のモノづくりを発信していきたいと願っています。

会社概要

会社名: 株式会社 Beat Communication (カブシキガイシャ ビートコミュニケーション)

設立年月日: 2004年1月6日

所在地: 〒107-0052 東京都港区赤坂8-5-28 AXIA青山906

代表取締役: 村井 亮

アクセスマップ

>FORTUNA Tokyo 公式オンラインショップ(日本語・国内用)

>>FORTUNA Tokyo グローバルオンラインストア(英語・海外用)